Within the development community, we are all talking about the intent of Bill 23. How will we go about building 1.5 million homes in Ontario by 2031, 187,500 homes a year for the next eight years when we have averaged only around 70,000 homes a year in the last eight? To achieve this dramatic increase will require a fundamental shift in our approach to both design and construction delivery.

- What is a Platform approach to Design for Manufacture and Assembly (P-DfMA) and how does it work?

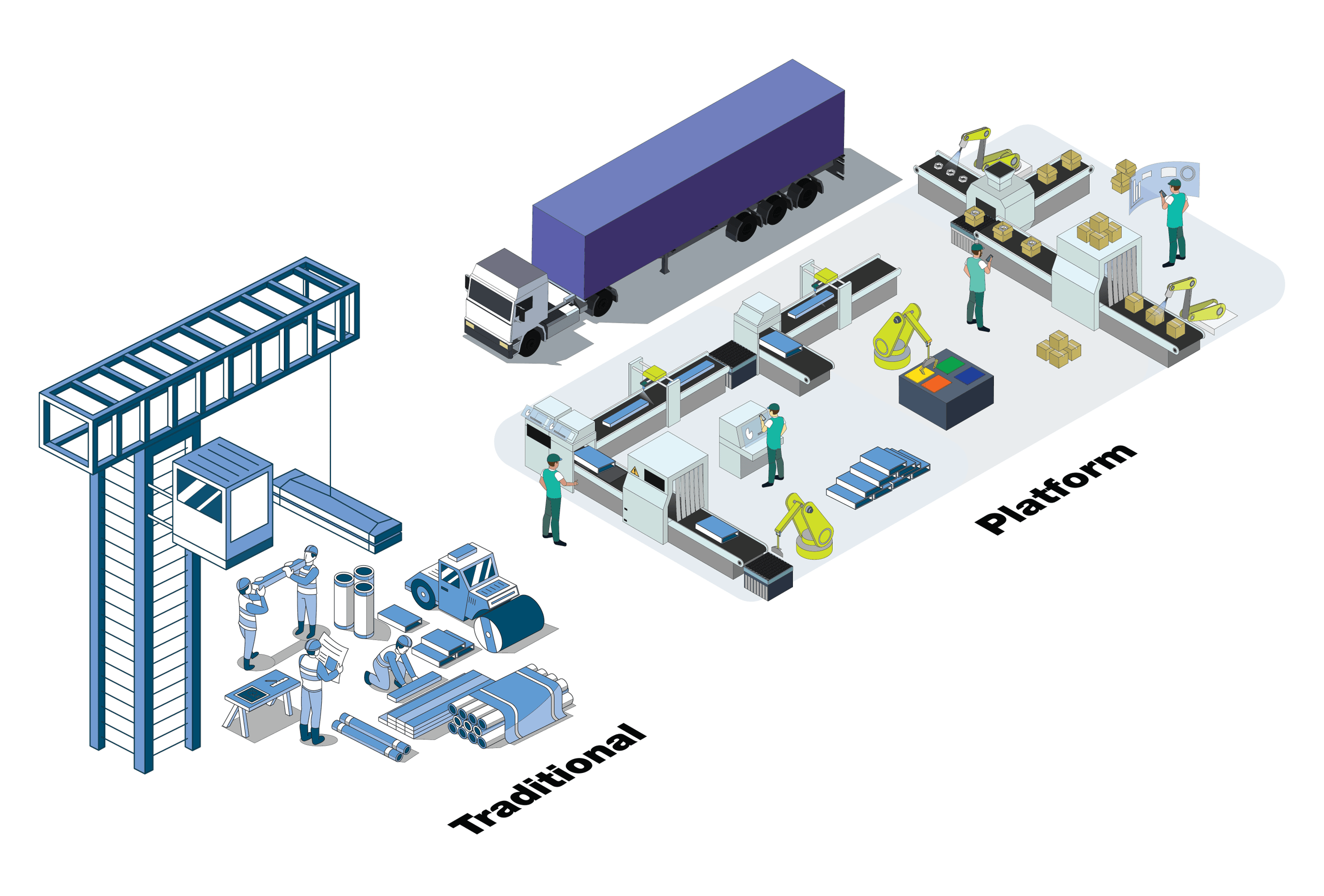

We need to break the P-DfMA terminology into its constituent parts to provide a clear definition. Design for manufacture and assembly (DfMA) is a term which was first used in manufacturing, centered on two design considerations: how a component is manufactured, and how it can be assembled into a product. Together, these considerations have the potential to yield efficiency in production. Much of today’s construction is based on the more traditional Design for Use approach, with limited adoption of DfMA.

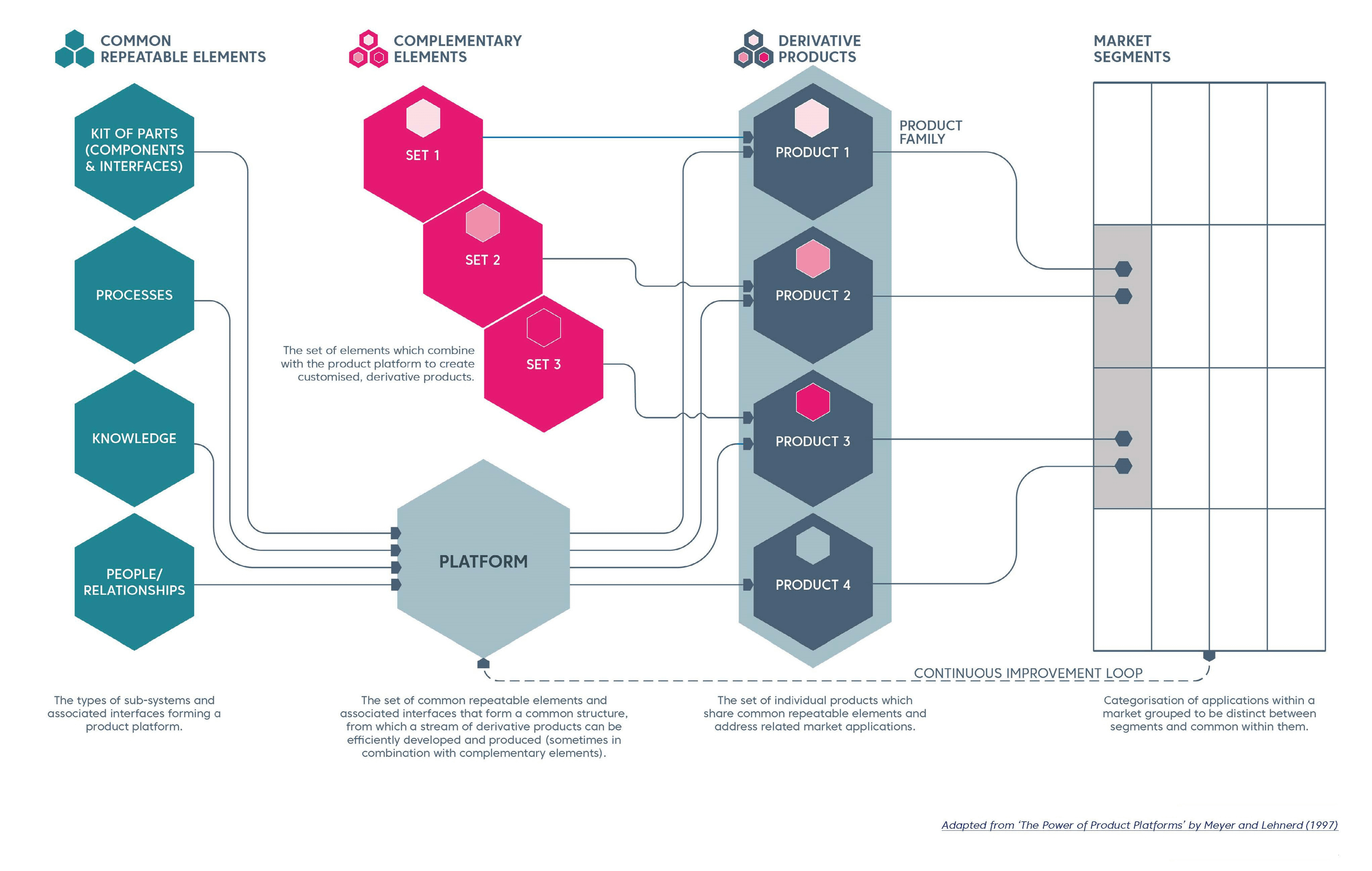

While DfMA construction projects can find commonalities within a single project, in its simplest application, these commonalities are often not transferable to future projects. A platform approach looks for commonalities between sectors and pipelines of multiple projects. Platforms can be defined as:

• Processes, equipment and tools required to assemble.

• Common repeatable elements which can be a kit of parts, knowledge, processes, people/relationships.

• A stable core which can be combined with other components via a defined interface.

Standard interfaces can bring together a combination of repeatable and common assets with complementary elements. This combination allows for the creation of product families that can serve a range of building types, sectors or market segments as illustrated below:

- Can a P-DfMA approach to construction help to address the affordable housing crisis?

If we are to build 1.5 million new homes in Ontario by 2031, while also meeting our Net Zero building targets by 2030, supply meeting demand is the first step, which means we need to build faster, to better environmental standards and do so more economically than we are able to do at present.

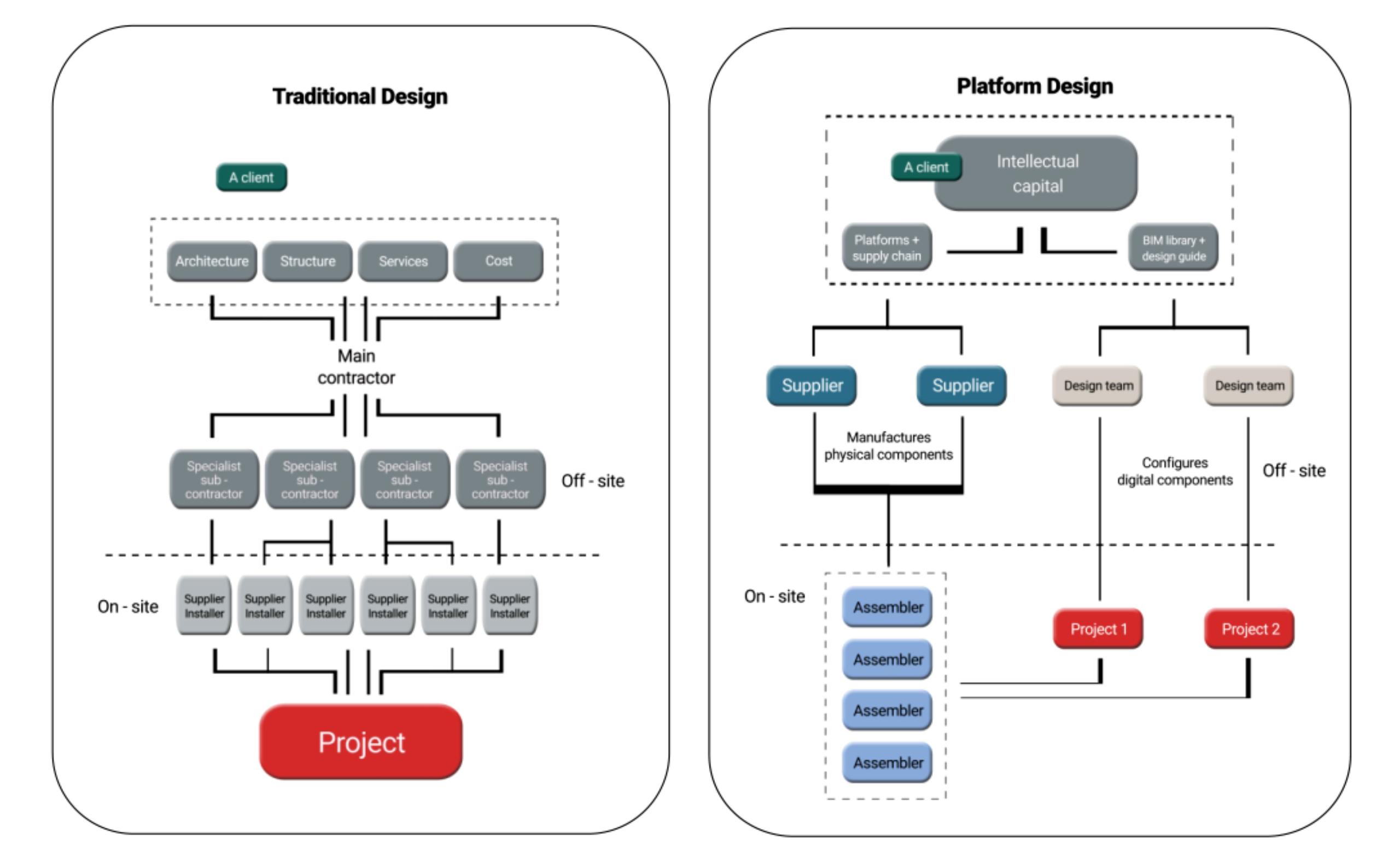

To achieve this, it is essential that we shift to a production mindset. With Building Information Modelling (BIM), we can leverage the reuse of knowledge, designs and processes to mitigate repeat work, unlock economies of scale and focus effort towards areas that add real value and continuous improvement. Platform principles will enable the construction industry to a manufacturing-led approach with a summary of benefits illustrated below:

Adding continuous improvements and the ability to optimize solutions; these are key benefits which are critical to the faster delivery of more homes to meet the growing demand. A platform approach to design for manufacture and assembly can bridge the gap between supply and demand in the residential sector.

- How can developers / clients adopt this approach in their work?

P-DfMA is as much a philosophy of construction as it is an approach. The philosophy must be imbedded at the beginning of the process in order to enhance DfMA beyond single-project benefits. The aim is that each project informs the next to build an integrated system design with the lessons learned from past projects improving the next.

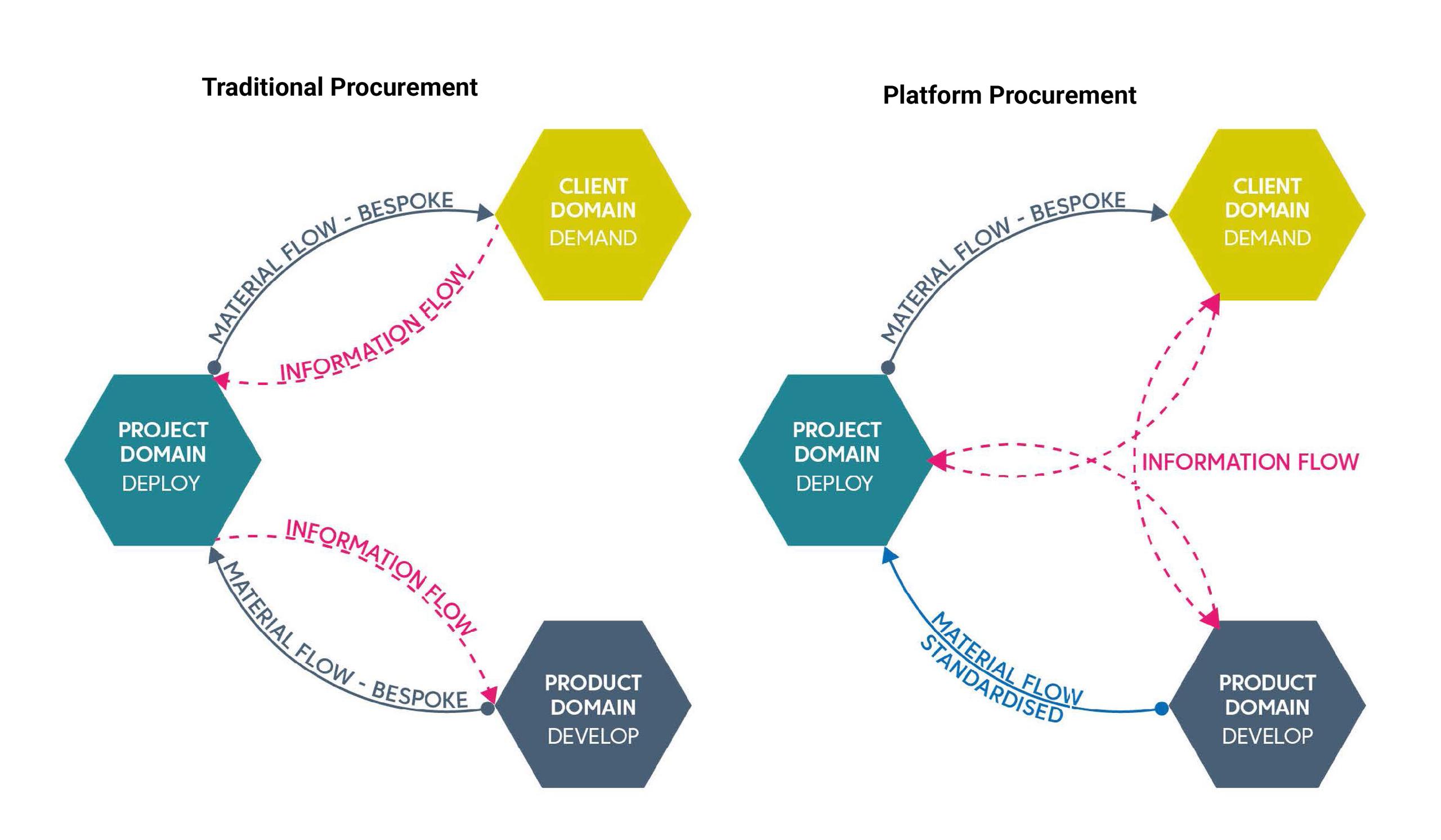

Every project is made up of three entities or “domains” from which information flows. In traditional project procurement, the information flow is sequential between domains, from client to project to product. With a P-DfMA, the relationship between the client, the project and the product are symbiotic.

This approach requires the client to engage much sooner with the supply chain, design team and contractor to define the platforms which will best suit the client’s needs. The approach requires that key decisions and elements of detailed design are front-loaded to drive discipline in the process to avoid unnecessary change.

The benefits are significant for clients working at scale, enabling traditional bespoke single projects to be transformed through a platform approach to delivery programs with the support of a committed supply chain. That supply chain can work across building sector typologies giving the flexibility to create more complex and varied residential mixed use programs. Platforms can achieve pipeline consistency and the economies of scale to unlock the benefits of manufacturing and still be achieved in the construction industry.

- Will a P-DfMA approach lead to “same-same” and monotonous design?

For many years, the manufacturing sector has been delivering mass-customized products leveraged from the reuse of common components and processes. The construction industry can do the same.

The chassis of a motorcycle or car, a web search engine or a smart phone are all examples of platforms which help to deliver customized products. In the construction industry’ the same rules apply. Monotony is mitigated by establishing a strategy to ensure that the platform is not too rigid to allow flexibility, variety and nimbleness to adopt future changes in technology and innovation. This strategy should also preserve functionality, performance and aesthetics. Defining a platform is not just a technical endeavor. There is a highly creative component to this process. Architecture remains very much at the core of this exercise, now more than ever before.

- Can P-DfMA create jobs and local employment & vocational training?

P-DfMA will utilize our limited skilled labour more effectively, enabling us to do more with this limited resource. The future of construction that embraces a manufacturing mindset will require the development of new exciting technology-based skills and new ways to work and collaborate. It will likely lead to an increase of niche jobs in construction geared to P-DfMA while also creating new jobs overall. The distribution of these jobs can be geographically broad, from sources of material supply through to points of assembly, to the site of construction. The industry has already embraced BIM, with coding and regenerative design software also emerging. These are likely to be the core digital platforms to share knowledge, communicate, visualize and drive P-DfMA in construction. A smarter more tech-based construction industry will have more appeal to today’s young adults now reaching working age as it is better culturally aligned to the world we live in.

How do we build 1.5 million new homes in Ontario by 2031 while meeting our net zero targets? Rather than delivering one project on one site at a time, we need to be delivering a planned pipeline of projects across multiple sites over the next eight years. A platform approach to design for manufacture and assembly is a solution to this pipeline delivery where the economies of scale maximize value while also enhancing quality.

_______________________________________________________________________________________

Works Cited

1 – Construction Innovation Hub + UK Research and Innovation - The Product Platform Rulebook

2 – RIBA – DfMA Overlay to the RIBA Plan of Work

3 – Bryden Wood - Delivery Platforms for Government Assets

4 – Bryden Wood - Bridging the gap between construction + manufacturing